Bold Step Technical Specifications

1. Product Nomenclature: BOLD STEP®

2. Company/Manufacturer Information: Sure-Foot Industries Corp. 20260 First Avenue Cleveland, OH 44130 Phone: 800-522-6566 Fax: 440/234-9098 Internet: www.surefootcorp.com

3. Product Description

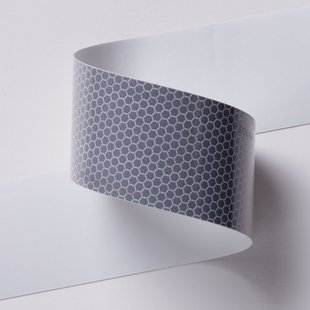

3.1 Basic Information: BOLD STEP® is an eye catching, resilient, anti-slip product for use on steps that require an antislip surface. Bold Step™ is an aluminum extrusion inlayed with anti-slip epoxy filler. Either used in new construction or renovation projects Bold Step ™treads, nosing’s and safety plates deliver maximum safety and durability while providing a look to compliment today’s building designs. Available in 7 standard colors plus Glow-in-the-Dark, Bold Step™ is strong enough for industrial applications, but attractive enough to be used at your residence.

3.2 Product Construction: BOLD STEP® is created using heat treated, exterior grade 6063 T5 aluminum. A proprietary blend of mineral abrasive grit and epoxy-filler creates an anti-slip surface available in Black, Yellow, Red, Blue, Dark-Green, Grey, Brown and Photo-luminescent. Bold Step™ is produced using materials that make the tread resistance to marring, scratches and chips. This product meets or exceeds the recommended value for slip resistance on wet and dry surfaces.

3.3 Product Types

3.3.1 BOLD STEP Renovation Treads Overall thickness: .25” (6.35mm), Width: 2.6” (Nose, single cavity), 4” (Nose, single cavity), 4” (Nose, 2 cavities), 7.5” (Nose, 2 cavities), 9” (Nose, 2 cavities),11” (279.4mm),

3.3.2 BOLD STEP Flat Safety Plates Overall thickness: .25” (6.35mm) Overall thickness: .25” (6.35mm) Widths: 3.5”, 5.5”, 7” w/ Tapered Ramp

3.3.3 BOLD STEP Anchor Nosings Overall Thickness: .25” (6.35mm),Width: 3” Anchor Nosing, 4” Anchor Straight Edge

Lengths: made to order Maximum 144” (3,667.6mm)

Fractions of an inch acceptable with tolerance Weight per Lineal Foot: 2.6” Nosing 0.75lb, 3.5” Safety Plate 0.75lb, 4” Nosing 0.95lb, 5.5” Safety Plate 1.2lb, 4” Anchor 1.55lb, 7.5” Safety Plate 1.5lb, 7.5” weighs 1.9lb, 9” weighs 2.2lb, 11” weighs 2.76lb

3.4 Technical Data

*ASTM E 648 (NFPA 253), Critical Radiant Flux:

Class1, <1.00 W/cm2

*ASTM E 662 (NFPA 258), Specific Optical Density of Smoke Generated by Solid Material;

Passes <450

*ADA Visually-Impaired: Yellow and Black color combination treads meet A.D.A.

recommendations for contrasting colors

*California State Code Title 24: clearly contrasting color combinations

4. Packaging

This product is made to order and ready to install upon delivery. The treads come with predrilled counter-sunk holes and optional screws to fasten the treads on steps.

5. Installation

5.1 General Preparation and Conditioning

All materials are to be delivered to the installation location in its original packaging with label intact. Product should be stored in Flat, Level, Dry areas. DO NOT STACK! Surface must be level, smooth, clean and dry. If desired, paint surface before installing treads. Product, surface and ambient temperatures must be above adhesive recommendations before installation. Items needed for installation: Drill, bit, Construction Adhesive, Chalk line, Treads and screws.

5.2 Surface Applications

5.2.1 Concrete

Fill and patch all holes making the step surface flat and smooth. If step is bowed or nose is rounded use a cement filler to ensure the step is level. Make certain the surface is clean using an industrial cleaner. Rinse the surface thoroughly to remove any soap residue. Allow surface to dry completely. If desired, paint the surface before installation.

5.2.2 Wood Floors

Replace any areas of wood that are bowed or severely worn, creating a flat, smooth, level surface. Make certain the surface is clean using an industrial cleaner. Rinse the surface thoroughly to remove any soap residue. Allow surface to dry completely. If desired, paint the surface before installation.

5.2.3 Metal Floors

Remove any flaking rust or paint. Make certain that the steps are level and smooth. Clean surface with industrial cleaner and rinse completely to remove any soap residue. Allow surface to dry.

5.3 Adhesive information

Constructive adhesive for sub-floors and decks. Follow application instructions on adhesive to ensure best results. Should be applied in ¼” bead around each screw hole, around the edge of the tread, front, back and side approximately ¼’ from the edge and complete with a zigzag formation across the bottoms of the tread. Allow 24 – 48 hours for the adhesive to fully dry

5.4 Adhesive application and Product Installation

Ensure that the step surface is flat, smooth and level before installing the treads. You will need a center punch, a hammer, a drill, drill bit, adhesive, chalk line and screws. Place one tread on the top step and another tread on the bottom step. Center both treads on the steps. Take the chalk line and stretch it from the left side of the top step to the left side of the bottom step and snap it. This will offer you a placement guide line for the rest of the treads. Starting at the top step and

using a tread as a template, use the center punch and mark where each pilot hole needs to be. Then remove the tread, using the drill with the bit, drill your pilot holes for the step. Tap each pilot hole. Clean off any drill shavings from the step. Turn your tread over and apply the adhesive. Place a ¼’bead around each hole, ¼” from the edge of the tread and in a serpentine pattern across the bottom of the tread. Line the tread up and place the tread in place. Using the

drill, fasten the tread in place.

6. Product Maintenance

6.1 Initial Maintenance

Remove and clean any adhesive product off the treads immediately. Wait 72 hours before cleaning the treads with an industrial cleaner and water.

6.2 Regular Maintenance

Surface can be swept to remove any loose dirt. Treads can be cleaned using a general purpose industrial floor cleaner. For caked on dirt use a stiff bristled brush with the industrial cleaner. BOLD STEP® products can be pressure sprayed up to 1500 psi.

6.3 Aggressive maintenance

Grease or Tar: Use small amounts of charcoal lighter fluid on paper towel

Dispose of towel in proper flame proof container

Chewing gum: Use aerosol Mellow Craft Chewing Gum Remover

Aluminum Nose: Spots, Marks and Scuffs, use green Scotch-Brite pad length-wise direction

7. TDS / MSDS

BOLD STEP® stair treads are defined as a manufactured article, see below;

ARTICLES

An "article" means a manufactured item: (1) which is formed to a specific shape or design during manufacture (2) which has end use function(s) dependent in whole or in part upon its shape or design during end use; and (3) which does not release, or otherwise result in exposure to, a hazardous chemical under normal conditions of use.

Any product which meets the definition of an "article," would be exempt from the

requirements of the Standard. For example, a roll of copper electrical wire sold to a hardware store would fit this definition of an article, but a load of copper ingots being shipped to a computer chip manufacturer would not (and would require an MSDS).

The definition has been amended to permit the release of "very small quantities, e.g., minute or trace amounts" of a hazardous chemical and still qualify as an article provided that a physical or health risk is not posed to the employees (59 F.R. 6146). In evaluating an article, one must consider the health risk which exposure to that article presents. (The term "risk" as opposed to "hazard" is used here, since the hazard is an inherent property of the chemical and exists no matter the quantity of exposure. To be exempted as an article, exposure must not pose a risk to employee health.)

Note that OSHA cannot make an across-the-board determination of a products'

exclusion as an "article." The standard's definition by its very wording imposes the need to make case-by-case evaluations. Consequently, a blanket exemption for specific products cannot be given by OSHA.